PRODUCTS

- PSA OXYGEN GAS PLANT

- VPSA OXYGEN GAS PLANT

- PSA NITROGEN GAS PLANT

- BIOGAS PURIFICATION PLANT

- Heatless Air Dryer

- HOC Dryer

- LOW PRESSURE DRYER

- Compressed Air System

- WATER TREATMENT PLANT

- CHEMICAL & DESSICANTS

- INSTRUMENTATION & ELECTRICAL

ON-SITE OXYGEN PRODUCTION: INDISPUTABLE ADVANTAGES

- Operating cost reduction: Clients investment is profitable within 1 year

- Elimination of the supply disruption risk: Oxygen is directly produced on site.

- No more supply constraints: gain time and get rid of usual logistics constraints (purchase orders, delivery slips, invoices, inventory management...)

- Enhanced safety: no more heavy bottles to handle, no more storage of high quantities of combustive gas, under pressure or in liquid cryogenic form.

- Reduced environmental impact : no more truck rotations for oxygen delivery

The Basic PSA PROCESS: A HIGH TECHNOLOGY

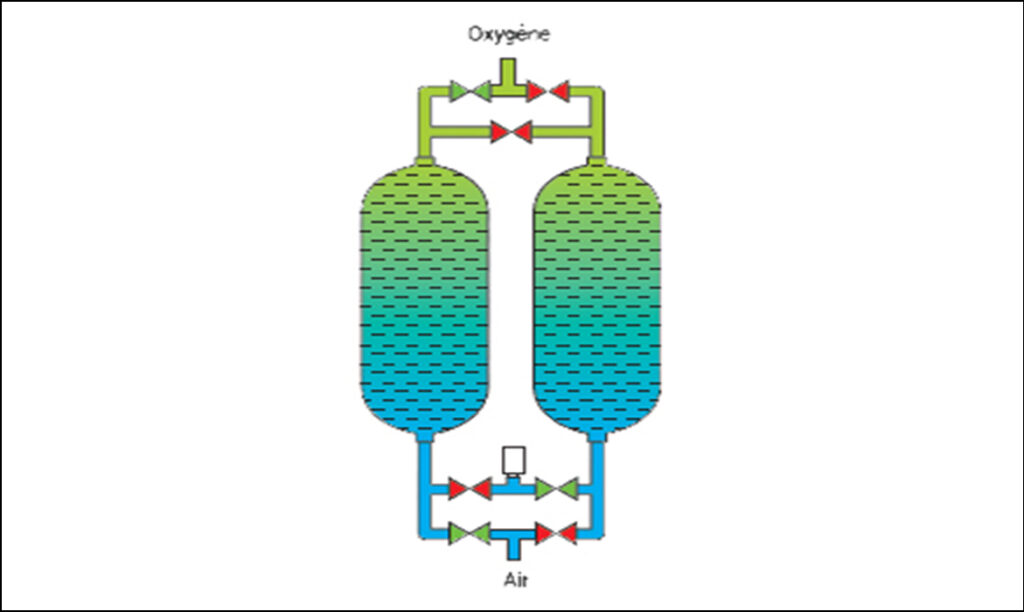

- The oxygen generator is based on a patented implementation of the Pressure Swing Adsorption (PSA) which uses ambient air as raw material.

- Ambient air contains 21% oxygen, 78% nitrogen, 0.9% argon and 0.1% rare gases. The PSA process is a static separation of air gases via a specific molecular sieve designed to adsorb nitrogen under pressure, to produce oxygen-enriched air composed of 93% oxygen and above.

- The oxygen generator is mainly composed of 2 separation vessels filled with molecular sieve adsorbers (zeolites), one complete pneumatic system (valves, filters, pressure regulator...) monitored by an automatic device, and an oxygen tank.

PSA Process Stage

Main Stage

Process Description

- Compressed air (78% nitrogen, 21% oxygen, < 1% argon) is filtered, degreased and dried and the production pressure is automatically regulated.

- Air passes through the molecular sieves where nitrogen is adsorbed by the zeolite, increasing oxygen concentration up to 95%.

- Out of the molecular sieve, the oxygen produced is sent through the buffer tank via a multifunction block. Nitrogen is released via a silent escape and forced back outside.

- Part of the oxygen produced is used to help the nitrogen desorption of one vessel while the other ensures oxygen production (and vice versa).

- An automatic and pneumatic vessels balance system ensure a continuous oxygen flow.

Utility of Oxygen Gas Plant

- Chemical Oxidation

- Welding

- Melting

- Brazing

- For Hospitals

- Manufacturing Batteries

- Glass Industry

- Copper Smelting

- Sewage Treatment

- Fish Farming

- Pulp and Paper Industry

| Parameters1 | ISO 10083 | United States USP XXII Oxygen 93% | European Pharmacopeia Europeans Oxygen 93% | Chaalak Industry Plant – Technologies | |

|---|---|---|---|---|---|

| Oxygen | O2 | > 90% | 90% – 96% | 90% – 96% | Orlane 93% ±3 Premium 95% ±1 Oxystar 99.5% |

| Carbon monoxide | CO | < 5 ppm | < 0.001% | < 5 ppm | < 2 ppm (0.0002%) |

| Carbon dioxide | CO2 | < 300 ppm | < 0.03% | < 300 ppm | < 150 ppm (0.015%) |

| Sulphur dioxide | SO2 | – | – | < 1 ppm | 0 ppm |

| Nitrogen oxides | NOx | – | – | < 2 ppm | 0 ppm |

| Water | H2O | < 67 ppm (-50°C) | – – | < 67 ppm (-50°C) | < 3 ppm (-75°C / -107°F) |

| Oil | – | < 0.1 mg/m3 | < 0.1 mg/m3 | < 0.1 mg/m3 | < 0.063 mg/m3 |

VPSA OXYGEN GAS PLANT

We are leading manufacturers and exporter of VPSA Oxygen Plant. When ZMS is used in the VPSA process, Nitrogen Molecules, having a higher diameter than Oxygen Molecule, passes through the pores and are adsorbed. Therefore, the Oxygen is recovered, while Nitrogen is adsorbed. Adsorption of Nitrogen Molecules happens at Low pressure, which makes it efficient & suitable for higher flow rates.

Salient Features of VPSA Oxygen Gas Plant

- Quick and convenient start and stop

- Low investment and energy consumption

- High automation

- Simple operation and maintenance

- Short installation period and small ground treatment workload

Industrial Application

- Metal gas welding, cutting and brazing

- Metal industry

- Chemical and petrochemical industries

- Fish farming

- Glass industry

Technical Specifications

| Flow Rate | 200-500 Nm3 / hr |

|---|---|

| Purity | 95 % |

| Pressure | 2-150 Barg |

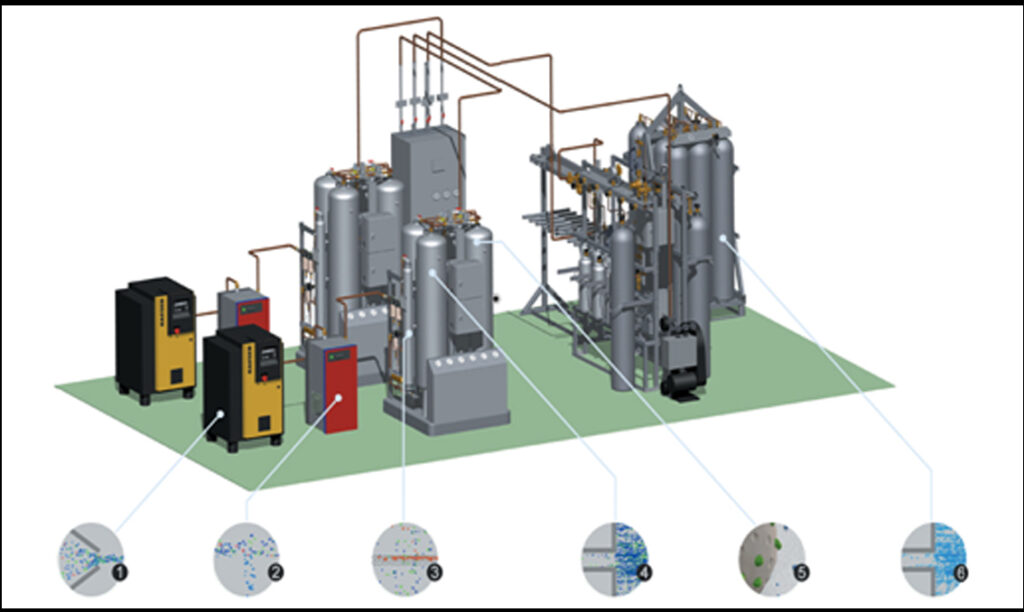

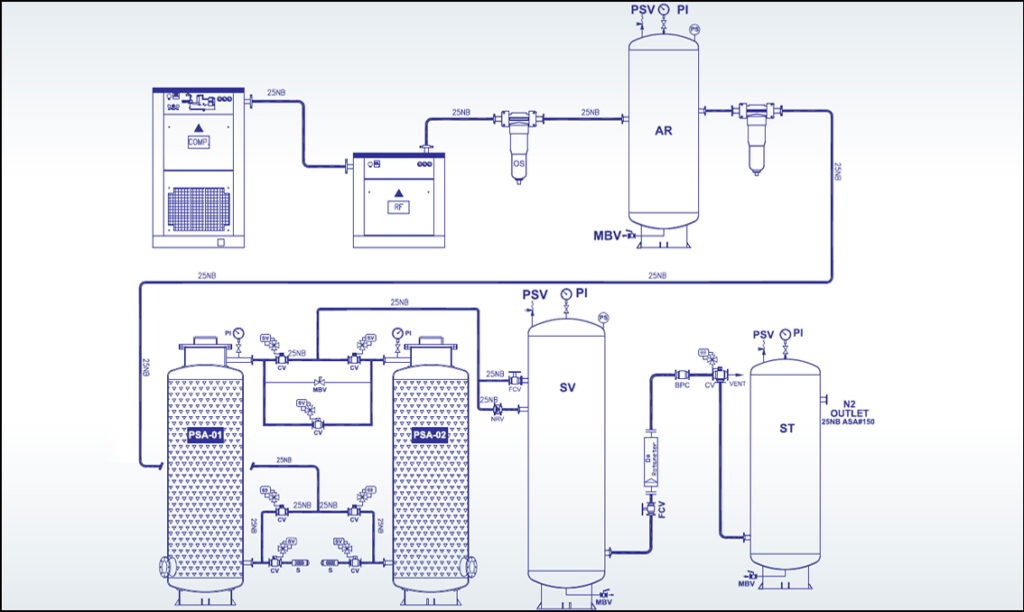

PSA NITROGEN GAS PLANT

We are Dealing in PSA based Nitrogen Plant. We manufacture and Commissioning more than 250 Plant from last 15 years. Our PSA Nitrogen Gas Plant ranges from 5 Nm3 to 5000 Nm3/HR as per customer’s Requirement. At Chaalak Industries, we listen to your demands and design the best possible solution for you. You can get the full line from air compressor to high quality cylinders – whatever your need may be. We design your specific solution based on application, capacity, purity, pressure, classification requirements, ambient conditions, and height above sea level. The more info you can provide us with, the better the solution we can deliver.

Product Specifications

| Type | Nitrogen Gas Plant |

|---|---|

| Production Rate | 500000 |

| Automatic Grade | Semi-Automatic |

| Purity (%) | 99.9999 |

| Power | 15 Watt (w) |

| Weight (kg) | 1 Tonne |

| Color | 1Other |

| Production Capacity | 5 m3/hr |

| Computerized | Yes |

| Control System | PLC Control |

| Voltage | 230 Volt (v) |

| Working Pressure | 7.5 kgf/cm2’ |

| Dimension(L*W*H) | 1.2×2.5×3 Meter (m) |

| Warranty | 12 month |

Nitrogen Gas Applications

Food & Beverages

Pharmaceutical

Electronics and Laser Cutting

Oil & Gas

Mining and Mineral processing

BIOGAS PURIFICATION PLANT

We are leading manufacturer and supplier of Biogas Purification Unit for our highly respected customers. Our offered unit is highly desired by our customers as it features high tensile strength, minimum maintenance, dimensional accuracy and long service life. Before dispatching, our quality analyst examine this unit on various parameters to ensure it flawlessness and durability. We offer this Biogas Purification Unit to customers in different specification at cost effective prices. Biogas is a renewable source of natural gas generated from the anaerobic digestion of waste materials in municipal landfills, waste water treatment plants and anaerobic digesters processing agricultural and industrial organic wastes.

BENEFITS OF BIOGAS PLANT

- Production of Renewable Power

- Treatment of a Waste Material

- Reduced Carbon Emissions

- Production of Coil Improver

- Cost Effective Proven Technology

Product Specifications

| Type | Biogas Purification |

|---|---|

| Material | Metal |

| Computerized | No |

| Automatic Grade | Automatic |

| Voltage | 220 Volt (v) |

| Weight (kg) | 50-60 Kilograms (kg) |

| Color | Red |

| Warranty | 1 Year |

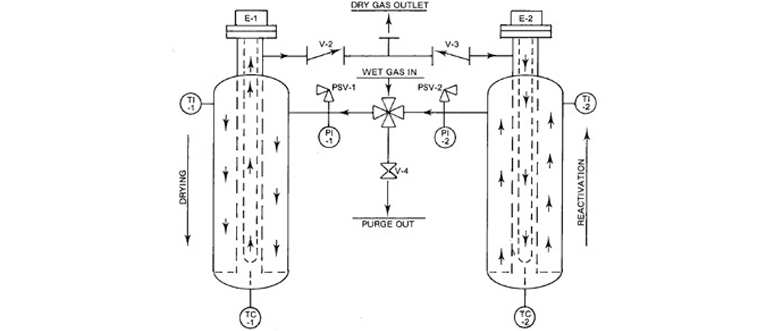

Heatless Air Dryer

We have gained a remarkable position in the industry by manufacturing and supplying a qualitative range of Heatless Air Dryer Unit to our valued customers. This precisely designed unit is formulated with the help of modern technology. It features space savvy design, excellent performance and longer working life. Before dispatching, this unit is tested by our quality inspectors on several parameters. In addition to this, the offered Heatless Air Dryer Unit can be purchase from us at best of market price.

| Color | Blue |

|---|---|

| Weight | 400-500 Kilograms (kg) |

| Power Output | 230 Volt (V) |

| Power Input | 230 Volt (V) |

| Temperature | 30 Celsius (oC) |

| Heating Power | other |

| Length | 1 Meter (m) |

| Size | 1x2x3 |

| Product Type | Air Dryer |

| Place of Origin | Ahmedabad |

| Dimension(L*W*H) | 1x2x2 Meter (m) |

| Inlet Temperature | 30 Celsius (oC) |

| Pressure | 7-8 kgf/cm2 |

| Power Consumption | 300 Watt (W) |

| Width | 3 Meter (m) |

| Height | 2 Meter (m) |

| Usage | Instrument |

| Noise Level | 45 db |

| Power Mode | AC |

| Power Source | Electric |

| Lubrication Type | Oil Free |

| Voltage | 220 Volt (v) |

| Warranty | 1 Year |

H.O.C. Air Dryer

Challak Industries Heat-Of-Compression dryers are most reliable dryers in terms of design innovation & performance. Our H.O.C dryer is equipped with advanced level of control panel thar maintains performance & monitors the health of plant.

Key Features:

- Energy Efficient

- Flexible in Design

- Clean & Dry Air

- Advanced Control System

- NO PURGE LOSS

- Atmospheric dew point of (-) 600C can be easily achieved.

Product Details:

| Usage/Application | Industrial |

|---|---|

| Dryer Horse Power | 10 HP |

| Minimum Output Dew Point | -20 C |

| Frequency | 50 Hz |

| Phase | 3 Phase |

| Material | Stainless Steel |

| Flow Rate | 5 to 4000 Nm3 / Hr |

| Weight | 6000 Kg |

| Voltage | 220V |

No Purge Loss Air Dryer

With the extensive knowledge and experience in this respective domain, we are engaged in offering high-quality Purge Loss Air Dryer. We only use high-grade raw material and the latest technology while manufacturing this Air Dryer. This Air Dryer is widely appreciated all over the nation for its salient features.

Features:

- No purge loss.

- No need of blower.

- No used of external air thus eliminating the risk of contamination.

- Most economical in the range from 400 CFM onwards.

Product Details:

| Usage/Application | Industrial |

|---|---|

| Minimum Output Dew Point | -20 C |

| Frequency | 50 Hz |

| Phase | 3 Phase |

| Material | Mild Steel |

| Automation Grade | Automatic |

| Flow Rate | 5 to 4000 Nm3 / Hr |

| Voltage | 380 V |

| Operating Pressure | 0.5 – 50 Bar |

Internal Heated Type Air Dryer

We provide the finest quality range of Internally Heated Air Dryer Unit which precisely crafted at our well-developed production unit. It is formulated with the help of modern techniques. It is highly acknowledged in the market for its features such as space savvy design, excellent performance and longer working life. Before dispatching, this unit is tested by our quality inspectors on several parameters. Furthermore, our esteemed clients can avail this Internally Heated Air Dryer Unit from us at market leading prices.

Features:

- Saving in purge air loss.

- Dew point up to (-) 80 Deg C (atm) can be achieved.

- Compact design.

- Simple operation

- Most economical in the range from 200 CFM – 1000 CFM

- Advanced Version of Desiccant Dryer with saving in purge air loss.

Product Details:

| Material | Stainless Steel |

|---|---|

| Automation Grade | Manual |

| Voltage | 380 V |

| Dryer Type | Regenerative Dessicant Dryer |

| Model Name | E TECH – IHD |

| Flow rate | 5 to 4000 Nm/ hr |

| Dew Point | -40 to -80 Degree C |

| Operating Pressure | 0.5 – 50 Bar |

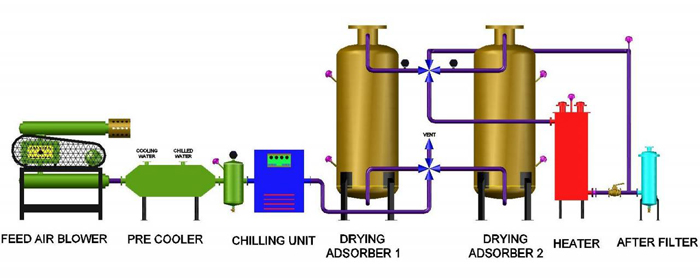

Low Pressure Air Dryer

Low-Pressure Air Dryer is passed over a special grade of desiccant in twin tower system. While one tower is under drying cycle, air is passed over an electrically heated other tower and carries out the moisture of this tower. Similarly based on time cycle change over takes place from the first tower to second to first. The operation is fully automatic.

Applications:

- Synthetic Fiber Industry

- Chemical Process Industry

- Air Curtains

- Other MISCL Industrial Application

Product Details:

| Usage/Application | Industrial |

|---|---|

| Minimum Output Dew Point | -20 Degree C |

| Frequency | 50 Hz |

| Material | Mild Steel |

| Automation Grade | Automatic |

| Model No. | E TECH – LPD |

| Flow rate | 1 to 10000 Nm / Hr |

| Operating pressure | 0.5 -1 Bar |

Refrigerated Air Dryer

Refrigerated Air Dryers are designed using high-grade components and advanced technology by our skilled professionals. In order to ensure the quality, these air dryers are stringently tested on various parameters. Clients can avail these air dryers from us in different configurations, as per their needs.

Features:

- Simple and compact design

- Automatic cleaning of the condenser

- Least pressure drop

- Easy maintenance

Product Details:

| Automatic Grade | Automatic |

|---|---|

| Frequency | 50 Hz |

| Phase | 3 Phase |

| Pressure | 0.5 to 12.5 Barg. |

| Refrigeration | R22 |

| Voltage | 415 V |

| Capacity Range | 5 to 1000 Nm3/ Hr |

| Dew Point | -23 Degree C |

Hydrogen Air Dryer:

Hydrogen Gas Dryers provided by us are highly efficient, thus needs less energy and provides excellent performance. Hydrogen Gas Dryer is easy to use and install. This is a dual tower, open regeneration type of dryer, a dual tower of vessels – one in drying mode and one in standby or regenerating mode. We uses inlet and outlet dew point measurements, via dew point transmitters, to determine the efficiency of the dryer as well as to control if and when the “in service” tower needs to be regenerated.

HEAT OF COMPRESSION TYPE AIR DRYERS

In Heat of Compression Type Air Dryers, directly from Air compressor discharge is taken to Air dryer inlet through insulated pipelines, at 120o C (minimum) temperature. This hot air is passed through one drying vessel where saturated desiccant is regenerated by this hot air. After picking up moisture from desiccant bed, the air is cooled in an intermediate cooler. Here moisture is condensed and removed by auto drain valve. Cooled to 40o C, this air passes through the second drying vessel where balance moisture gets adsorbed and Dry air comes out. Cycle time is 4 hours regeneration & 4 hours drying. After 4 hours the changeover of vessels takes place automatically. In regeneration cycle heating of the bed is only 2 hours, and thereafter the bed is cooled by Dry air. After bed cooling, Dry air is again cooled to 40o C in another cooler, and delivered out of unit as Dry air at 40o C temp. The Dryer is fully automatic with pneumatically actuated Ball/ plug valves. A sequence timer controls operation of these valves. Desiccant used is Activated Alumina and it dries the air up to (-) 40o C Dew point

Salient Features

- Easy maintenance

- Trouble free operation

- Longer life of desiccants

- Fully automatic operation

- Low pressure drop

- Highly efficient as there is no loss of compressed air

Technical Specifications

| Air Capacity | 500 to 6000 NM3/ Hr. |

| Dew Point | up to (-) 60oC. |

LOW PRESSURE DRYER

In Blower Purge Offering low pressure air dryer, low pressure nitrogen dryer, fully automatic and computerized air handling unit for use in synthetic fiber, chemical process, air curtains and other industrial applications.

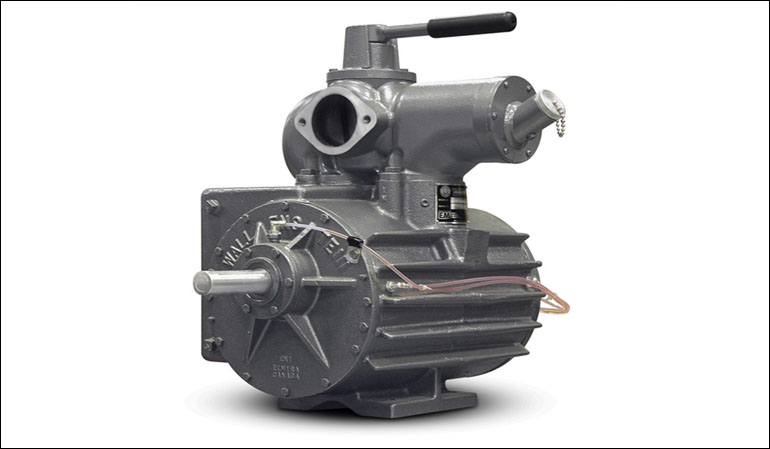

Compressed Air System

We have emerged as a leading organization, engaged in offering superior quality 10HP Heat Of Compression Air Dryer. Our offered air dryer is manufactured by our skilled professionals using high-grade components and latest technology in compliance with the industry quality standards. In addition to this, our provided air dryer undergoes various tests under the supervision of quality controllers to ensure its flawlessness. Our offered air dryer is available for our clients at a very convenient range of prices.

In non-lubricated air compressors, a great amount of heat is generated which is lost due to cooling in after cooler. In heat of compression type dryer, this heat is utilized to heat the air for regeneration. In this dryer hot compressed air is passed through a heater to maintain the temperature around 180 Deg C, which is then passed through the desiccant bed for regeneration. After taking out the moisture this air is cooled in an aftercooler where moisture is condensed and drained out in moisture separator. Then this cooled air is passed through the other tower of desiccant for drying.

Features:

- No purge loss.

- Saving on electrical Heater load.

- The atmospheric dew point of (-) 600C can be easily achieved.

- Most economical in the range from 300 CFM onwards

Limitations:

- Can Be used with Oil Free Compressed Air Only.

Industrial RO Plant

Basic & Specialty Chemical for different types of Water Treatment Plant

Air Blower & Vacuum Pump

Ultra Filtration Unit

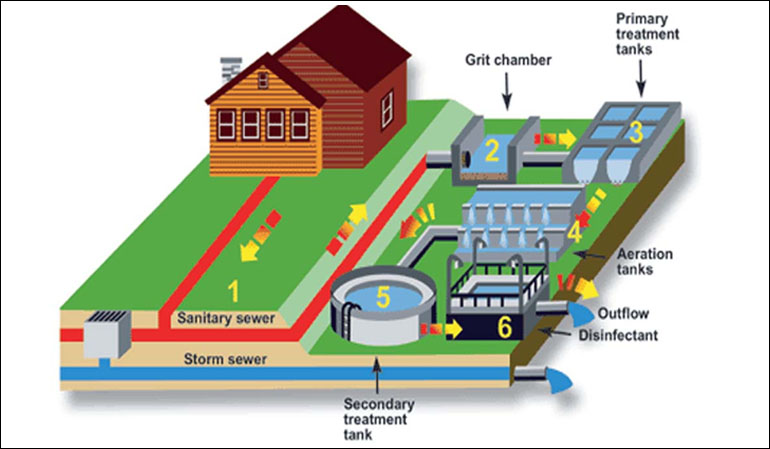

Water Treatment Plant (WTP)

Sewage Treatment Plant

Effluent Treatment Plant

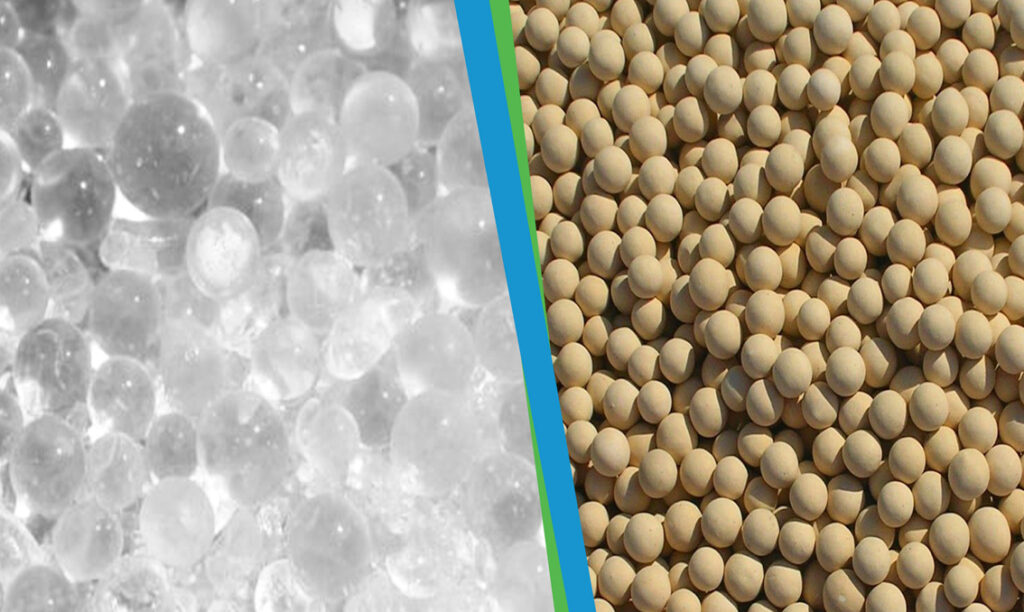

Carbon Molecular Sieves

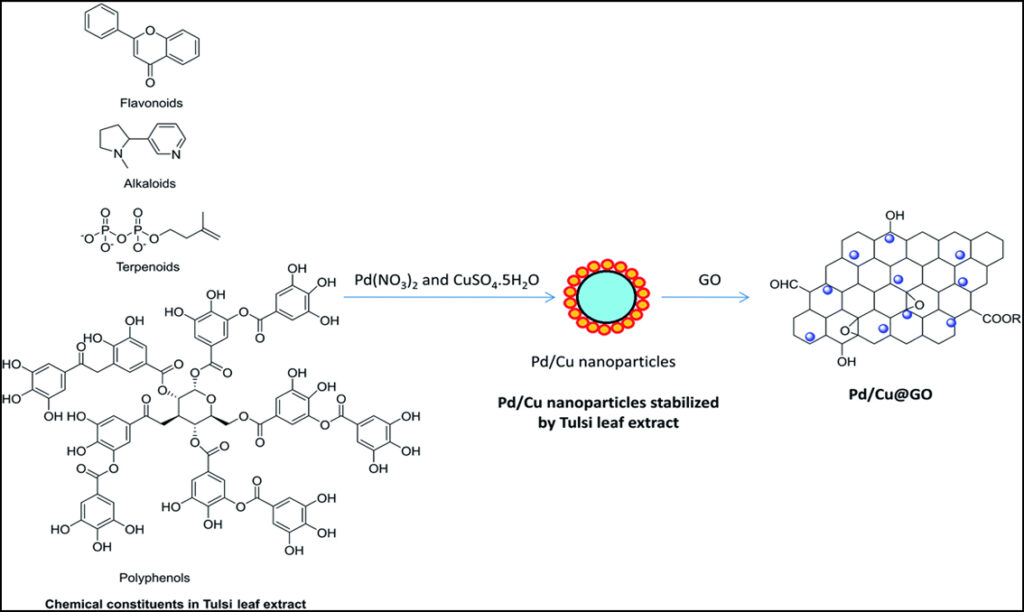

Cu, Ni & PD Catalyst

Zeolite Molecular Sieves

RO Anti Scalants & PH Booster

Speciality Chemicals for RO Plant, DM Plant, STP Plant, ETP Plant, Boilers Heat Exchangers, Cooling Towers and other Water Cleaning System.

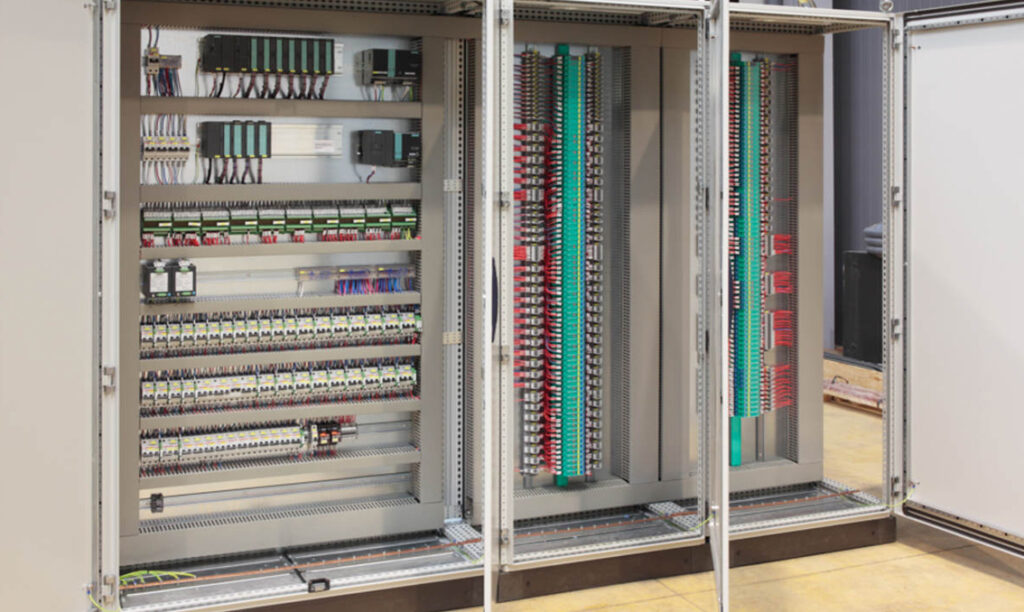

Power & Control Panel with suitable Interlock & Field Instruments for any System

Gas Analyzer & Sensors

Panel Enclosures as per required design

Field Instruments

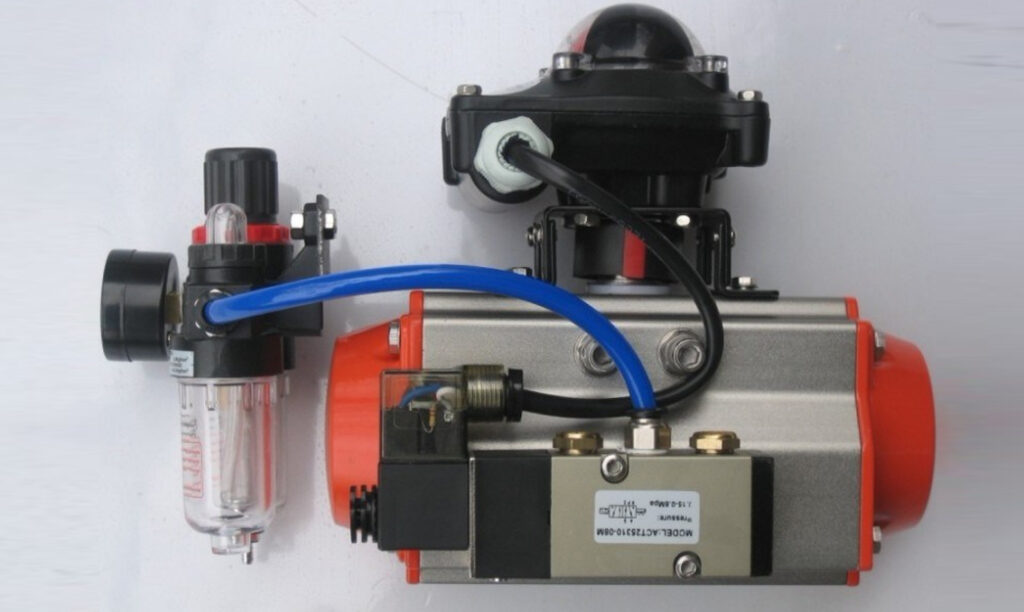

Solenoid Valves & Pneumatic Actuators